Two years after moving to Northern Virginia, I have finally put the finishing touches on my rocket barn. I’ll be publishing new updates, including all of the new goodies I’ve built and purchased for rocket building. Stay tuned!

Building Rockets for space in my barn

Two years after moving to Northern Virginia, I have finally put the finishing touches on my rocket barn. I’ll be publishing new updates, including all of the new goodies I’ve built and purchased for rocket building. Stay tuned!

Launched the “Airstream of Consciousness” yesterday at the Midwest Power XIII Rocket Launch in downstate Illinois. This was a hand made scratch built all-carbon fiber rocket using my filament winder for the airframe and a 10 ton press for the fins. Since Carbon Fiber attenuates (acts as an RF shield) my ham radio spectrum downlink, I used a traditional fiberglass nosecone and put the electronics there. I had 7 camera’s on the rocket! If you look closely, on the tip of the nosecone, I had a bubblcam. I was a kickstarter backer for this thing, it’s basically 4 video camera’s built into a spherical ball to take 360 video’s which can be played back on an oculus rift, Google cardboard, or on YouTube using a mouse. Unfortunately, the centripetal force on the camera due to the spin ejected the microsd card mid flight.

Video in all it’s glory:

The most common question I get from people who first find out I enjoy rocketry (after – “is it legal?”) is how the rockets are built, and what kind of tools do I use. I’ve recommended my own blog of course, but realized the level 3 build which started this blog didn’t discuss any tools, or core manufacturing techniques at all. So, this will be a short tour through my workshop.

First, what I’m not going to show you – the “base” of my workshop looks a lot like someone poured a mechanic’s garage into a woodworkers toolshed, and threw in some culinary equipment. Drill press, table saw, giant mixers, scroll saws, bench sanders, and lots of tools. Nothing really special here, and I’ve tended to go cheap (think Harbor Freight) on many items because I just don’t use them often

and I’ve tended to go cheap (think Harbor Freight) on many items because I just don’t use them often  enough to appreciate the difference. I guess the one tool in this area that is not found in your average garage is a TIG welder. There are some areas in rocketry in which there is no better alternative then metal, in my case, aluminum. Think motor cases, push rods, even fins. This is an alternate view of my 99 mm aluminum tig-welded fincan that fits perfectly over a 98 mm motor case, which I will be using as the booster section of a minimum diameter sounding rocket I am working on.

enough to appreciate the difference. I guess the one tool in this area that is not found in your average garage is a TIG welder. There are some areas in rocketry in which there is no better alternative then metal, in my case, aluminum. Think motor cases, push rods, even fins. This is an alternate view of my 99 mm aluminum tig-welded fincan that fits perfectly over a 98 mm motor case, which I will be using as the booster section of a minimum diameter sounding rocket I am working on.

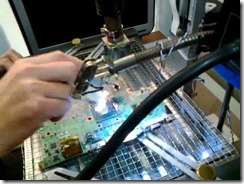

The fun begins with equipment not often found in your typical shop. I build a lot of electronics for fun, including custom electronics for rocketry. While the boards themselves are milled on my cnc machine (which you’ll see in a bit), most of the fun is in my basement office, which happens to also

The fun begins with equipment not often found in your typical shop. I build a lot of electronics for fun, including custom electronics for rocketry. While the boards themselves are milled on my cnc machine (which you’ll see in a bit), most of the fun is in my basement office, which happens to also be a good soldering bench. With the number of soldering guns and stations I own, you would think I’d be good at it by now, but I’m not. I’m like the baseball player that can’t hit the ball, but sure can run the bases. In this case, I often stumble in the original build, but I’ve gotten really good at reworking a board. In fact, my reflow and rework station equipment is professional grade including IR camera’s and a robotic arm to help my sausage fingers manage the tiny SMT bits and pieces being made today. One of my old hobbies was collecting vintage computers, which provided me hours and hours of electronics board repair training. At one point in my life, I was lucky enough to own an Apple 1, and successfully brought it back to life. I’ve also spent a week rebuilding the electronics in a McDonalds happy meal that stopped working, and brought my eldest daughter to tears……

be a good soldering bench. With the number of soldering guns and stations I own, you would think I’d be good at it by now, but I’m not. I’m like the baseball player that can’t hit the ball, but sure can run the bases. In this case, I often stumble in the original build, but I’ve gotten really good at reworking a board. In fact, my reflow and rework station equipment is professional grade including IR camera’s and a robotic arm to help my sausage fingers manage the tiny SMT bits and pieces being made today. One of my old hobbies was collecting vintage computers, which provided me hours and hours of electronics board repair training. At one point in my life, I was lucky enough to own an Apple 1, and successfully brought it back to life. I’ve also spent a week rebuilding the electronics in a McDonalds happy meal that stopped working, and brought my eldest daughter to tears……

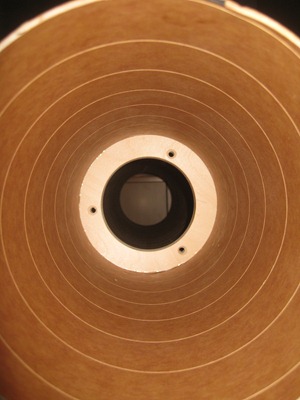

Next up is a filament winder. This is a computer controlled machine which which allows me to make the rocket sustainers, and other parts out of any kind of filament. Think carbon fiber, fiberglass, Kevlar. basalt, etc. These highly specialized machines normally cost 50,000 to 100,000 dollars. An enterprising guy named Turner Hunt decided to try and make a hobby version, and launched a kickstarter . The first one didn’t go so well, but the second was successful. The entire machine is built with 8020 extruded aluminum, and the same stepper motors I use in 3d printing. The secret sauce is in the software, which can control the number of wraps, and the angle of each wind to create very specific circumferential, or longitudinal tensile strength.

I have done extensive development in openscad to allow me to model different winding angles and build the profile perfectly before even starting a part. In this video I am winding a 6” diameter carbon fiber sustainer, which you will see fly in a video later this year. You can see more videos of the filament winder on one of my YouTube channels.

My second favorite tool is my home made CNC machine. a CNC machine is basically a router, or spind

le bolted to a computer controlled gantry. I sure do love tools controlled by computers! In this case, I can build on my computer exactly what I want cut out in 3 dimensional space, then the CNC machine will do all the work to very, very tight tolerances. Makes things like fins, AV bays and centering rings trivial to make to exact specifications. What is really exciting about a CNC machine is it can go well beyond the basic building blocks, to build extremely complex parts. The x-15 build lower on the page c ould not have been built without a CNC machine. In this video, one of my daughter’s had designed her pinewood derby car on the computer, and we let the CNC machine do all of the work. Needless to say, she won first place in the “best design” category.

ould not have been built without a CNC machine. In this video, one of my daughter’s had designed her pinewood derby car on the computer, and we let the CNC machine do all of the work. Needless to say, she won first place in the “best design” category.

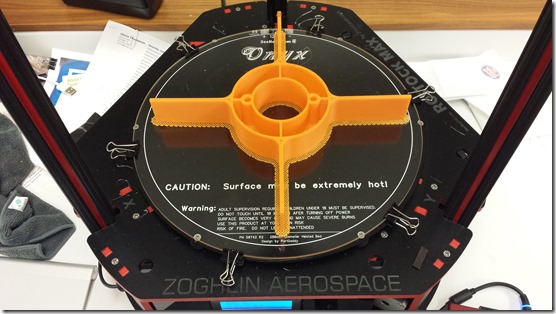

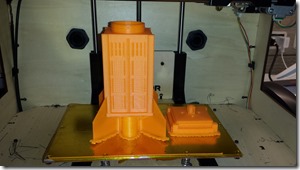

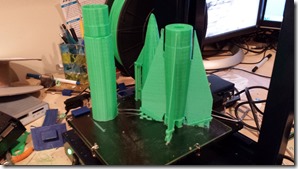

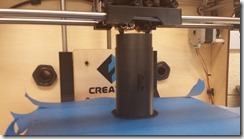

While I’ve talked about 3d printing in a previous post, I should point out I now own 6 different 3d printers, each one getting bigger, and more complex. The “Zoghlin Aerospace” delta printer to the left can build objects over 12” in diameter, 3 feet high. In this photo, it’s building a 4” rocket with integrated fins, and all internal components except the electronics are integrated as it prints. printing the entire rocket at once allows you to build extremely detailed rockets that would be very time consuming, if not impossible using traditional techniques. In the photo b

While I’ve talked about 3d printing in a previous post, I should point out I now own 6 different 3d printers, each one getting bigger, and more complex. The “Zoghlin Aerospace” delta printer to the left can build objects over 12” in diameter, 3 feet high. In this photo, it’s building a 4” rocket with integrated fins, and all internal components except the electronics are integrated as it prints. printing the entire rocket at once allows you to build extremely detailed rockets that would be very time consuming, if not impossible using traditional techniques. In the photo b elow I was able to integrate a complete Dr. Who callbox into a rocket, and print out the entire rocket and flat nose cone at the same time. As you can see with the green rocke

elow I was able to integrate a complete Dr. Who callbox into a rocket, and print out the entire rocket and flat nose cone at the same time. As you can see with the green rocke t, I can also create traditional rockets, and print out all of the parts at once. If you would like t0 see more, I have several rocketry related 3d prints available on my account thingiverse including

t, I can also create traditional rockets, and print out all of the parts at once. If you would like t0 see more, I have several rocketry related 3d prints available on my account thingiverse including  modular 38 and 54mm rockets, rocket camera holders, and most of the parts for a complete Saturn V (photo of it completed is lower down on this page).

modular 38 and 54mm rockets, rocket camera holders, and most of the parts for a complete Saturn V (photo of it completed is lower down on this page).

While I use a lot of 3d modeling software products including Inventor, Solidworks, Aspire, there are times when you just want to make a copy of something physical. I have three laser scanners, and a structure I/O device which allow me to take real objects and dynamically build models out of them. In the photos below, I scanned a statue of wife. The laser scanner interprets the statue as tens of thousands of points in space (called a pointcloud). I can then use this pointcloud to create a mesh, which ultimately creates a 3d model. The blue version is the finished 3d model, which looks exactly like the original statue. I’ve scanned lot’s of things, and once again you can find them on thingiverse if you have any interest.

Most of the laser scanners are like the my AIO robotics – a moving platform, and a scanning laser combine to create slices of an object. This works great for small objects, but when they start to get big, it becomes more and more expensive, not to mention the time to get a working model. The Structure I/O (object with a white cover on it) connects to my iPad, and uses the iPad camera, combined with it’s own depth sensors to build models in real time by just moving the iPad around an object. This allows me to get much larger objects, vehicles, people, architectural accents, etc. I scanned my youngest daughter with the structure I/O, then used the model to create a rocket noscone that looked exactly like her head. I scanned a Harpoon missle at the museum of science and industry, then used the dimensions to assist with the harpoon you see lower in the website.

My last major toy is a laser cutter. I don’t need to say much about this one, it’s a big freakin’ laser, controlled by my computer, that can cut almost anything. The version I have is an industrial one, I always keep an eye out for manufacturing equipment that looks like it’s being sold cheap on craigslist. In this case, I was able to get a commercial very large 100w laser with lot’s of accessories (liquid chiller, blower, exhaust system, auto-focus, red dot) for a fraction of the cost of even a low power hobby one.

I have other “toys” in the workshop, like a mini-mill and a 4th axis router, but they are just variations of the wonderful machines I’ve already highlighted. Finally, as I’ve become more proficient in the computer controlled machines, I’ve been able to branch out, and build similar machines that don’t go into my workshop, but are used by the family for other crafts. Below is my Christmas ornament maker. It’s a CNC machine for designing Christmas ornaments. Instead of a spindle, we just put a pen, and away it goes.They made great presents this year.

Sorry for the EXTREME delay between posts! Work has been getting the better of me. Given how much knowledge and equipment I’ve collected over the years to build rockets, I’ve found these skills are useful for building other fun electronic projects. I received my pilots license over twenty years ago, but let both the skills, and my license (my medical) lapse long ago. The bug bit me recently to freshen up, and I was amazed at what the state of the art in simulation looked like. Like rocketry, there is a small, but dedicated community of enthusiasts that have made some amazing amateur simulators. While I don’t exactly have the room for a full blown simulator, I was able to build a simulated cockpit panel, and mount it on a movable metal pole to refresh my piloting skills.

I also happened to build a few rockets too :> As soon as we have a warm weekend, I’ll take them out for a photo session. The most common question I get is what tools do I use to build all of these things. In the next installment, I’ll take you on a walk through my laboratory (My wife call is the garage) of CNC machines, laser cutters, filament winders, 3d printers, reflow stations, laser scanners, PCB etching equipment and random tools I use.

Finally launched the monster motor.

Rocket weighed over 150lbs on the pad. Apogee was at 14,375 ft, and landed about 1.5 miles from the launch site in a small forest. My eagle-eyed daughter saw the parachute caught at the top of the largest tree.

The name of the rocket is a shoutout to the hosts of a podcast called no agenda which can be found at http://www.noagendashow.com/ . The show should be required listening for the rocketry community – especially after the Bureau of Alcohol Tobacco and Firearms tried to shut down the hobby.

Had a great time at Tripoli Wisconsin’s launch today at the Richard Bong State Park (Bong to us local’s) just over the boarder in Wisconsin. Tim “Wildman” Lehr grilled the entire crowd

Had a great time at Tripoli Wisconsin’s launch today at the Richard Bong State Park (Bong to us local’s) just over the boarder in Wisconsin. Tim “Wildman” Lehr grilled the entire crowd  free lunch! Work has kept me from most of the launches this year, so this was my first time launching from our new spot in parking lot “E”. The spot isn’t bad, except it’s right next to the bathrooms which limits our ability to launch anything larger than a K motor. Hopefully with the announcement of LDRS coming to Bong next year we will once again be able to use our primary spot in the middle of the park. The weather was absolutely beautiful and perfect for flying. I participated in the annual Minie

free lunch! Work has kept me from most of the launches this year, so this was my first time launching from our new spot in parking lot “E”. The spot isn’t bad, except it’s right next to the bathrooms which limits our ability to launch anything larger than a K motor. Hopefully with the announcement of LDRS coming to Bong next year we will once again be able to use our primary spot in the middle of the park. The weather was absolutely beautiful and perfect for flying. I participated in the annual Minie  Magg

Magg

drag race, even though I didn’t even know it was scheduled! One of my daughter’s liked the look of the rocket, so we brought it along. Unfortunately, I didn’t stick the landing

drag race, even though I didn’t even know it was scheduled! One of my daughter’s liked the look of the rocket, so we brought it along. Unfortunately, I didn’t stick the landing ![]() . Parachute didn’t deploy, so I had to scrape the remains of the rocket off the side of the road. Also launched my scratch built Nike

. Parachute didn’t deploy, so I had to scrape the remains of the rocket off the side of the road. Also launched my scratch built Nike Smoke. Perfect Launch, but it went so high it landed in the back half of the park which is all swamp and lake. We never did find it

Smoke. Perfect Launch, but it went so high it landed in the back half of the park which is all swamp and lake. We never did find it ![]() . Kids had a blast launching from the low power pads. Tried several new rockets, including a few gliders with mixed results. One big lesson… don’t put an ammonium perchlorate based motor into a light glider. We spent quite a while picking up the shredded pieces across the flight line. My good buddy Aaron brought two of his boys up to watch as well. Always fun to see new kids get excited about the hobby.

. Kids had a blast launching from the low power pads. Tried several new rockets, including a few gliders with mixed results. One big lesson… don’t put an ammonium perchlorate based motor into a light glider. We spent quite a while picking up the shredded pieces across the flight line. My good buddy Aaron brought two of his boys up to watch as well. Always fun to see new kids get excited about the hobby.

Wow!

I can’t believe it’s been almost 6 months since my last update. I guess life has been getting in the way. I certainly haven’t given up on rockets – if anything, my other hobbies have been suffering at the expense of rocketry. Spent the winter building, and rebuilding several rockets. A 98mm carbon fiber minimum diameter rocket (Like my old Tachyon here), a Ultimate Wildman (a platform to test some video hardware), and a Saturn V. The Saturn V is about 1/35th scale – as you can see in the photo, it’s significantly larger then my Redstone at almost 11 feet tall. What makes this Saturn V interesting is many of the parts on the rocket were built using my 3d printer. I’m currently working on the 3d model for the Launch Escape Tower. You can download my model from thingiverse page here. Just a word of warning – while the model is finished, it’s not printing correctly. I may need to

way. I certainly haven’t given up on rockets – if anything, my other hobbies have been suffering at the expense of rocketry. Spent the winter building, and rebuilding several rockets. A 98mm carbon fiber minimum diameter rocket (Like my old Tachyon here), a Ultimate Wildman (a platform to test some video hardware), and a Saturn V. The Saturn V is about 1/35th scale – as you can see in the photo, it’s significantly larger then my Redstone at almost 11 feet tall. What makes this Saturn V interesting is many of the parts on the rocket were built using my 3d printer. I’m currently working on the 3d model for the Launch Escape Tower. You can download my model from thingiverse page here. Just a word of warning – while the model is finished, it’s not printing correctly. I may need to  add a raft, and some supports to ensure the build works. The 3d printer itself is an absolute blast. I can’t tell you how much of my free time I’ve wasted. I recently acquired a nextengine 3d laser scanner which essentially allows me to laser scan any object, then print it on my printer. I’ve become my own bespoke reverse engineering manufacturing plant in my basement. You can see some of the 3d scan’s I’ve done on my thingiverse page linked above.

add a raft, and some supports to ensure the build works. The 3d printer itself is an absolute blast. I can’t tell you how much of my free time I’ve wasted. I recently acquired a nextengine 3d laser scanner which essentially allows me to laser scan any object, then print it on my printer. I’ve become my own bespoke reverse engineering manufacturing plant in my basement. You can see some of the 3d scan’s I’ve done on my thingiverse page linked above.

I can basically print an entire rocket ready to launch. This particular rocket is so light and strong (ABS plastic, extruded with a 15% fiill) it doesn’t need a parachute, or even a streamer.

Finally launched the Harpoon!

Flawless launch at Midwest Power 10. Only real issue is I lost the fairing that covered my Go Pro camera, but that was actually by design. I was really worried the fairing would collapse and I would loose any good video. I had read about making an Adruino motion sensing switch on a blog at the University of Illinois Engineering website (my Alma Mater) a few years back and thought it would make an interesting solution to my issue. I built a few prototypes, and eventually settled on a design that would blow the fairing off the rocket if a photosensor detected returning laser radiation over a specific threshold. In the video below, you can see the fairing collapse right at 1:55), the Go Pro picking up the laser dot, then shortly afterward, the fairing is blown off the rocket by a small BP charge. Watching the landing from the ground, I was also a bit worried at the end that the rocket would land on a local farmhouse. Luckily, it missed by a few hundred feet.

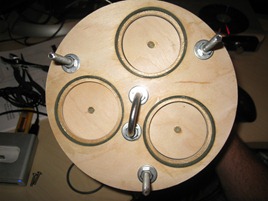

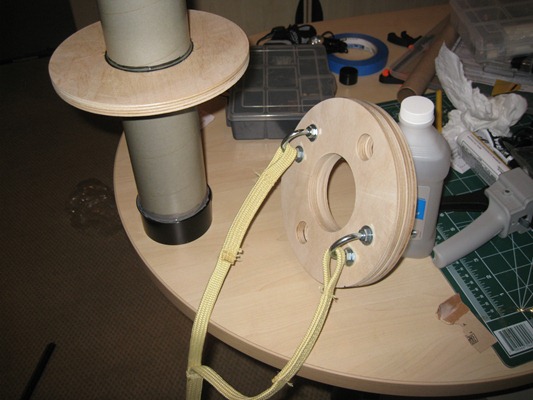

The Harpoon has a very unique booster. I can reconfigure the rocket as necessary to fit any configuration of Motor’s I want within a 7.5” tube. Here’s a few photo’s to try and show how it works.

I’ll I have to do is make a new thrust plate, and centering rings to fly a completely different motor configuration. 100% of the motor thrust is transitioned to the bottom of the rocket, where it should be.

Next year The Harpoon will fly on one large 150MM center motor, and several smaller air starts for effect. In the meantime, most of my winter building will be on a super-secret new project……

Due to my schedule, and the fact my local rocket club doesn’t fly experimental motors, I only get to launch EX motors once a year, and Midwest Power in Princeton Illinois. EX motors are just that – typically a rocket propellant you whip up yourself in your garage, or basement. The big advantage of manufacturing your own motors is you can control a lot more variables. Want the flames to be red? add Strontium Nitrate. Need to speed up the burn rate of the propellant? Add Iron Oxide. Need an even thrust level through the entire burn? Try a Finocyl core geometry. You get the idea.

For the last few years, I’ve been trying to push the limit on making a slow-burning propellant. This is much more difficult than changing up the chemical composition because the longer the propellant burns, the more exposure the motor hardware, nozzle, and liner will have to the heat and pressure. Worse, the core geometries with the longest burn characteristics (endburner & moonburners) tend to keep the heat and pressure focused on a particular part of the case for an extended period of time. Once a formula is stable enough to flight test, I typically try them first in an oddroc saucer. They are very light – easy to lift of the pad, very stable – no fin alignment issues, and don’t fly very high – easy to recover just in case…..

In 2011, my longburn test ended in disaster. The propellant burn was so low, the rocket never got off the pad and eventually burned through the motor case, destroying the saucer, rocket motor, and the pad it was sitting on. All of this was caught on video at Midwest power 9 for your enjoyment

Needless to say, I spent a year with the nickname “firestarter” by everyone that witnessed this first attempt.

A year

later, with dozens of changes and testing of the propellant formula, I returned to Midwest power in the hopes of a successful launch. The good news is the launch was successful – the saucer zoomed off the pad. The bad news is my nickname may now be permanent… After a successful flight, the rocket caught fire on decent and started a small field fire. Once again, I was left with a destroyed rocket and motor. Of course, my daughter caught the whole flight on her iphone while I was clicking away on the still camera. At least I have another year for research!

Saucer and 75mm EX motor ready for launch

launch sequence

And the recovery……

This is all I got back, some burnt carbon fiber and a ruined rocket motor

My wife and kids are off at the inlaws this weekend, so I thought it would be a good day to do some clean up. I pulled out all of my rocket’s larger than 7.5” diameter for a group shot

From left to right: 7.5" / 10ft Patriot : 10" / 9.5ft Maximum Thrust Thunderbird : 11.5" /16ft Harpoon : 9.25" / 18ft Iris : 7.5" / 13ft Nuclear Sledgehammer

For perspective, I put a 4 Grain Cesaroni Pro150 in front of the Iris.

Another LDRS 31 has come and gone. As usual, the hosting club put together a really nice event. The first day was much like my first day at LDRS 30: hot and dusty. You can always tell the weather by how my feet look at the end of the day. I was scheduled to launch the Pizza rocket for the Discovery channel first thing Saturday morning. Of course, I had a major last minute electronics failure. My WRC+ handheld unit decided it didn’t want to turn on. It’s a matched pair to the transceiver in the rocket, which meant I had to replace the electronics entirely. A quick trip to Wildman’s trailer, and I was back in business with a missileworks PET2+ timer. I quickly built a sled to install it into the nosecone of the pizza, and reprogrammed it to go off about a half a second after engine burnout. I didn’t have the right equipment to install a power switch, so I opted for the “twist and go” method – this may have been my downfall.

LDRS 31 has come and gone. As usual, the hosting club put together a really nice event. The first day was much like my first day at LDRS 30: hot and dusty. You can always tell the weather by how my feet look at the end of the day. I was scheduled to launch the Pizza rocket for the Discovery channel first thing Saturday morning. Of course, I had a major last minute electronics failure. My WRC+ handheld unit decided it didn’t want to turn on. It’s a matched pair to the transceiver in the rocket, which meant I had to replace the electronics entirely. A quick trip to Wildman’s trailer, and I was back in business with a missileworks PET2+ timer. I quickly built a sled to install it into the nosecone of the pizza, and reprogrammed it to go off about a half a second after engine burnout. I didn’t have the right equipment to install a power switch, so I opted for the “twist and go” method – this may have been my downfall.

The good news is the Pizza had a great flight. I wasn’t too surprised at how well it flew, as I had at least 30 computer simulations before this launch. To build the simulations, I had to make a lot of assumptions (guesses…) because the underlying software was really built for traditional rockets, and wasn’t totally confident in the math, or aerodynamics. Since the Discovery channel was filming me as I was watching the rocket, I wasn’t able to video, or photo the launch although – I did get some video of the setup, and the discovery channel film crew before the flight

Luckily, several other people were taking photo’s that day, and Chris Dondanville was nice enough to upload all of his photo’s to flickr. Below is a nice burst of shots of the Pizza rocket launch

The bad news is the new electronics malfunctioned, and the parachute failed to come out. Either I programmed the electronics wrong (unlikely – I checked the programming after the launch), or the battery failed. I didn’t anticipate that the rocket would sit idle on the pad for about two hours in 100+ degree heat before the launch. I opted to use a radio shack private label brand nine volt battery. Probably a bad choice given the environment.

The rocket is very light for it’s size (about 30 lbs), with a lot of drag, and it’s built like a tank. Crash landing had absolutely no effect on the rocket that I could find – it’s ready for the next flight. At the end of heat one, I was in the lead of the odd roc competition, primarily because every rocket before mine either cato’d, or disintegrated in flight. I can’t reveal whether or not I won ![]()

I fellow park flyer commented the other day that my blog doesn’t adequately represent my rocket collection, and frankly, he’s right. My girls are enamored with finding things around the house and yard and asking “Dad, can you turn this into a rocket”. The answer is usually yes. About 80% of my rockets are actually odd-roc’s, so I’ve decided to post some photo’s of just a few in my collection. Yes, you’ve seen my night launch saucer, my dining room table w/ pizza, and my collection of crayon rockets, but that’s just a small sample. An odd-roc is any rocket design that isn’t the basic 3FNC, which is three fin’s and a

girls are enamored with finding things around the house and yard and asking “Dad, can you turn this into a rocket”. The answer is usually yes. About 80% of my rockets are actually odd-roc’s, so I’ve decided to post some photo’s of just a few in my collection. Yes, you’ve seen my night launch saucer, my dining room table w/ pizza, and my collection of crayon rockets, but that’s just a small sample. An odd-roc is any rocket design that isn’t the basic 3FNC, which is three fin’s and a  nosecone. I’m a big saucer fan – in fact I’m beta testing Art Applewhite’s largest delta design to date – 36 inches in diameter. I’ll post a review after I’m finished with the build and first flight. I also found a kitchen sink at the dump the other day – that will be my ultimate test.

nosecone. I’m a big saucer fan – in fact I’m beta testing Art Applewhite’s largest delta design to date – 36 inches in diameter. I’ll post a review after I’m finished with the build and first flight. I also found a kitchen sink at the dump the other day – that will be my ultimate test.

UPDATE: This will now be flying at LDRS 31 in New York. I’ve dramatically reworked the electronics so I can now house a professional high speed HD camera in the gold exhaust port on the right side of the rocket.

Working on my major project for the Thundersrtuck Launch starting this Friday, March 30. Launch will be around 3pm March 30th.

This is a full size AGM-84 Harpoon Missile.

For perspective, that is an 8 foot ladder in the photo above

Thank goodness I’m in good shape – to get this photo I had to carry the two upper sections of the rocket solo up the ladder and into the booster.

I built this saucer for the annual MWP 9 Night launch. Since the night launch has a limited FAA altitude ceiling, traditional rockets just don’t cut it. The RGB LED’S on the saucer are controlled by an Arduino controller which I can control with my phone via Bluetooth. Cool to change the patterns while the saucer is on the pad.

Unfortunately, I wasn’t able to make the launch this year. Next year I plan on embedding the LED’S into the rocket in a matrix so I can transmit scrolling messages to the rocket from the pad kind of like this one, but much bigger

I was recently asked to go through some old photo’s, and found a bunch of old launch photo’s from loved, but long forgotten rockets. Here are a few:

This was a Rocketry Warehouse Halloween special which included a ‘pumpkin’ parachute..

This is an upscaled Este’s Snitch called “woket”. This particular rocket is still in my fleet, but undergoing MAJOR modifications to turn it into a night launch rocket. I’ll post some video when I’m done adding about 300 LED’S and batteries, and a computer controller to it. Should be an ‘interesting’ flight

Here is an original rocket vision machbuster.

I built this 10 years ago, and finally flew it on a cti f240 Vmax

rocksim indicated it would go 0 to 1200 MPH in about .3 seconds (which is the burn time of the engine), and reach about 4000 ft. I couldn’t fit a tracker on it, but decided to write my phone number on it just in case…..

When the motor lit, it sounded like an explosion. I had a 210fps video camera going, and only got 1 frame of the rocket leaving the pad, which means it was probably going faster than 1200 MPH by my calculations.

I can’t say much more. Nobody ever saw it, or heard from it once it left the pad. Still waiting for my phone to ring ![]()

Short update… Need to get to bed for the long trip home. Day two was just as hot and dirty as Friday. Local’s told me Argonia Kansas just passed their record for days over 100 degrees. When I got back to the hotel Friday night, I took off my sandals to the ugliest site I’ve ever seen – my feet! This town has redefined the word dirty for me. Looks like I have a wicked tan, but it’s just a few layers of dirt.

I was supposed to be in the “odd rocket” Discovery Channel competition on day two with the pizza rocket, but they ran really long and blew through the FAA waiver time before getting to my rocket. They asked me to come early on day three, but I was also in the “fastest rocket” competition, and I didn’t want to screw up all of the prep on that rocket for the pizza. Frankly, I was happy not to launch the Pizza because I have a feeling it will only survive one launch, and I really want to do it with my kids. Sorry Jim – didn’t get a chance to test the WRC+ in a live launch at LDRS, but I’ll be back at Bong in a few weeks.

Spent a fair amount of time being interviewed by Discovery Channel. Don’t know how much of the footage they will use, but it was fun, and I got my 15 minutes of fame (at least in my own mind ![]() ). Also got to meet Kari Byron, the host of Mythbusters. I have to say, I was a bit surprised how nice the crew was. Below is some photo’s my brother took of them taking video.

). Also got to meet Kari Byron, the host of Mythbusters. I have to say, I was a bit surprised how nice the crew was. Below is some photo’s my brother took of them taking video.

Jim Harris was nice enough to ship me a demo 98mm 11000 M1800BL rocket motor. He knows I love his black lightening motors. The motor still isn’t certified, but it sure seems done! My patriot went up over 15,000 feet! The crowd actually clapped at the launch. Jim’s a smart businessman, because I plan on buying the first 98mm certified motor he makes ![]()

Below is the pad video from the launch. Nadine was able to catch a few great photo’s of the launch – I’ll post them when they arrive.

Wow – I never realized Kansas could look and feel like Mars! Temperature today was 103 degrees, wind gusts of 25 mph, with a consistent breeze filled with dust and dirt ensuring no part of your body or equipment was going unpunished.

Because of the Wind, I was a little worried about sending up some of the rockets. Finally decided to send up the large flying saucer. As you can see, I got a bit dirty. They initially put me on one of the close pads, but when the pad manager saw the engine sticking out of the top, he talked to the RSO and shipped me out to one of the away pads. Good thing he did! I had a 54mm motor mount in this saucer – within 3 seconds of launch, the motor mount and motor ripped through the saucer and kept on flying – corkscrewing all the way up. We were able to find the saucer, and it didn’t have any damage. Unfortunately, I have yet to find the reloadable motor.

After a particularly bad experience with BP, I thought there had to be a better solution to rocket recovery than initiating a explosion inside the rocket. I want hot gases to exit the nozzle, not the nosecone!

I’ve been playing with several third party solutions.

The first was was the Chute Tamer. This is a neat idea which uses fishing line to keep the parachute folded, then initiates a ‘cuter’ by heating up an element which melts the fishing line. The filiment is initiated by a timer. I had two issues with the chute tamer. The first issue is it still required BP at apogee to pop the nosecone – either from a traditional altimeter, or motor ejection. Second, you have to do a fair amount of modeling and prediction to determine when the optimal time (vs. altitude) would be for main deployment. I started a conversation with the inventor, Warren Farr about replacing the timer with an altimeter. After a fair amount of back and forth, Warren was kind enough to sell me a few chute tamer’s that were modified to allow me to put my own electronics in. I spent a few months designing two alternatives

Both of these had “issues”, although I did eventually get concept #2 working. This was still only a half solution because it required BP for motor ejection at, or close to apogee. You can find the original chute-tamer here: http://www.chutetamer.com/introduction.shtml

The second product I stumbled upon was a spacetec SRM. This is basically a release mechanism operated by a standard RC Servo. What’s cool about it is the company sells a servocontrol unit which allows the SRM to be connected to a traditional altimeter. The SRM “Holds” the main in the rocket body until the altimeter determines it’s reached the proper altitude. Better solution than the chute tamer on multiple levels (uses an altimeter, no limit to the size chute, as it doesn’t use fishing lline) but still requires BP to eject the nosecone.

Finally, I hit upon an idea – what if I ejected the nosecone using electromagnets? I could easily build a circuit that would charge a very high voltage capacitor, then use an altimeter to initiate the capacitor circuit. I started doing some testing using an Este’s V2, and it worked!The nice thing about the V2 is it has a large diameter to fit all of the equipment, yet it’s really light. I was about to announce my invention to the world when I started having a series of failures starting at MWP 8. The system never failed, but the calculations I had been doing on repulsive magnetic force weren’t working – The electromagnets starting putting out such a large magnetic burst it was blowing the electronics out of the rocket. By now, I started work on my Level 3 certification and decided to put the electromagnetic ejection system on the back burner until I finished.

Fast Forward a year, and I finally found the right project to finish the system. I’ve been building “flying pie”, which is a spool pizza rocket for the last few months, but I found it very difficult to build a simulation to model it’s flight characteristics using traditional software. Add to to this the fact it’s a 75mm minimum diameter motor tube, which means I can’t rely on motor ejection at all (no commercial 75mm motors have motor ejection). In the few flight trials I did with the spool, the flight characteristics where so different than a traditional rocket the G switch timer, and altimeter had a hard time reliably detecting launch, and/or apogee.

Around this time, Darrell Mobley at RocketryPlanet told me that Jim Amos at Missileworks was going to be building an updated version of his WRC wireless control system. The WRC allowed the rocketeer to take control of the ejection process using a remote control rather than relying on a traditional altimeter. This seemed to be the perfect solution to initiate recovery on a rocket that traditional altimeters had a hard time with. Jim was kind enough to let me into the beta program for his updated wrc+. I will dedicate another post to a review of the wrc+, but the one line review is “awesome”.

Since I now had a reliable electronics, I decided this would be a good time to pull out the old electromagnets, capacitor charge boards, and rare-earth magnets to turn the pizza pie into my new magnetic sky lab.

using one of featherweights new magnetic switches so I didn’t have to cut a hole in the av-bay, or rocket.

I have two lithium batteries – one 9 volt to power the wrc+, and one 12 volt on a circuit with an opto-isolator (so I don’t blow the wrc+) and a 300 volt capacitor.

The capacitor is connected to the external terminal ports on the top of the av-bay. I then connected this to two electromagnet’s at the top of the rocket (cheap chinese – http://www.ebay.com/itm/20mm-12V-Holding-Electromagnet-Lift-2-5kg-Solenoid-/150638839722?pt=LH_DefaultDomain_0&hash=item2312c647aa#ht_1471wt_1164). In the nose cone, I have two large nickel-plated neodymium magnets glued into the nosecone bulkhead. The magnets are naturally attracted to the metal on the top of the electromagnets, keeping the nosecone on.

When I’m ready, I just use the wrc+ to initiate the capacitor, which energizes the electro-magnets, creating a short, but massive repelling magnetic force against the rare earth magnets in the nosecone, which should pop the nosecone if everything goes well….

Here’s the first test this afternoon:

Actually worked on the first try! While there was not a lot of force (I’m a bit gun-shy from my previous research) this rocket is probably ok, as the lamp shade will get caught in the wind pulling out the parachute.

Well, I’m scrambling to finish a few rockets for LDRS 30. I’ll be bringing at least 6 rockets. 3 oddrocs, and 3 ‘traditional’ rockets. Here’s a few photo’s

This X-15 is probably one of the most difficult builds I’ve ever done. I had to redo the fiberglass several times, and getting the fillets to look good on all of those contours was next to impossible. I wound up dipping my finger in alcohol, then hand creating the fillet. Not a process I want to repeat, but it’s nice to know you can get this much control.

I plan on entering this one into the Discovery channel oddroc competition. The Pizza is a photo of a dominoes pizza my family ate earlier in the summer.

Mark Hayes at Stickershock did a fantastic job making the Vinyl from my photo. Makes me hungry just looking at it! I had a heck of a time trying to simulate how this rocket would fly – we’ll see in a few weeks.

This is Tachyon, my entry into the “worlds fastest rocket”. It’s all plastic and hand laid Carbon Fiber. I’m not quite finished with the rocket, still needs some work on the inside, and I’ll be ordering from Vinyl for it to make it look a little nicer. The rocket itself weigh’s in at a bit less than 6 lbs. I will be putting a rocket motor in that weighs over three times as much, and will launch with twice the power of the Hennessey Viper Venom race car I sold to make room for my rocket collection…..

This one should look familiar. I’m bringing it along because Jim Harris at Gorilla Rocket Motors sent me one of his new 98mm Black Lightening motors to demo at LDRS (it’s not certified yet). This is a very sturdy rocket, and I know it will be able to handle the punch of his new motor. I’ve had to sand the nozzle down to fit his slightly modified liner – I hope it doesn’t CATO!

I’ll be bringing more rockets, but you get the idea.

Launched my Patriot a couple of weekends ago on my first Gorilla Rocket Motor. This is Jim’s version of an AMW skidmark – I think he may have actually created a better version! Certainly better then the CTI skidmark, or Aerotech metalstorm.

Well, the weather doesn’t look too good for a launch, but I’ll go up to see what the field looks like. My TAP members will be up there at a university launch event.

Launch will be held at the Richard Bong state Recreational area just over the boarder in Wisconsin (http://dnr.wi.gov/org/land/parks/specific/bong/index.html#directions). I plan on launching between 12 and 1 pm, unless the weather doesn’t cooperate again.

Since I had a few weeks of downtime, I’ve made some modifications to the rocket. Here’s a list for posterity:

Replaced the small screw switches I was using for power in the altimeter bays with large SPDT Push button switches. This will make it MUCH easier to reach into the rocket with a screw driver to turn on the electronics.

Added a much beefier ubolt and retention steel plate to each side of the altimeter bay. This was at the recommendation of one of my TAP sponsors, and a good one.

Ordered a giant 3/4” wing nut to replace the 3/4” bolt I was using to secure the nosecone bulkhead. This will let me insert and replace the bulkhead without any bulky tools.

Ground tested the upper sustainer ejection. Based upon the results (successful) I Reduced the amount of black powder I was planning on using, and repositioned one of the blastcaps.

tough weekend for the “questionable investment”.

Had to scrub the launch on Saturday due to bad weather. Sunday was a beautiful, sunny day, but 25-30 MPH winds. Looking to reschedule for early May (possibly the 7th, weather permitting)

Picked up the rocket from the Ultimate Paint Shop today. All I can say is: WOW!

The good news is they did a FANTASTIC job! Look at the paint on those fillets – all of my other rockets will look horrible in comparison. Oh well ![]()

The bad news is I have two days left to finish the rocket.

Things left to do:

a little rewiring on the AV-Bay. I found an intermittent short on one of the ematch wires. Better safe then sorry.

Need to weight all the parts and recompute the CD/CG. Determine if I need nose weight, then epoxy in the allthread into the nosecone. Also need to foam the nosecone, build some electronics compartments and install the forward bulkhead

I re-fit the AV bay into the upper sustainer, and retest the main parachute deployment. now that everything has been painted. I decided on redundant BP blastcaps for both the drogue and main deployment charges. Better safe then sorry, and I can always remove them later.

drill air holes, sheering pin holes, altimeter arming holes,altimeter breathing holes, and 1515 rail button mounting holes.

Sorry for the lack of updates. work and travel have taken over a bit.

T-2 weeks and counting until lift-off!

I’ve added a page for my pre-flight checklist. you can see it here: https://mylevel3.wordpress.com/pre-flight-checklist/ this is a work in progress, so let me know if you think I’m missing anything obvious.

My rocket now has a few sponsors! I took my rocket into a local automotive paint dealer, The Ultimate Paint Shop in Lake Bluff to get an early start on the paint job (weather has been bad in the Chicago area, they have an indoor paint booth). By the time I left their facility, I had two firm sponsors, with the possibility of adding more.

(weather has been bad in the Chicago area, they have an indoor paint booth). By the time I left their facility, I had two firm sponsors, with the possibility of adding more.

I checked with my TAP sponsors to make sure it would be ok to have ‘professionals’ finish the exterior – they were all for it. Feels a bit strange – I have no idea what the rocket is going to look like when they are done. I picked out the primary colors, but told them they could add their logo’s and names as necessary for the sponsorships. The one thing I can be sure of is the paint job will certainly look a lot better than if I did it.

In the meantime, I’ve been finishing up the programming on the Altimeters and prepping the GPS & trackers. I decided to add a terminal block for my raven to simply the connection process since it has a common ground. I also learned something new about my Marsa4. I’ve been running low on my ematch supply (Wildman ejection charge lighters), so I ordered a few Quest Q2G2 long’s to use as ematches. I use the Q2’s a lot for lpr rockets as they are very easy to set up, and are extremely reliable. The Q2’s require a very small current to go off. Turns out the Marsa4 puts out enough milliamps during it’s continuity check to ignite the Q2’s. Reinforces the “ground test, ground test, ground test” adage. I will use the Wildman ejection lighters for the marsa4, and the Q2G2’s for the raven.

I’ve gone through several more sanding / priming steps. Also managed to fit the custom nosecone to the sustainer. It’s starting to look like a real rocket! Unfortunately, it’s still cold in the Chicago area, so I’ve been forced to prime outside, then quickly bring everything back into the garage. My wife’s been pretty good about the horrible paint smell, but this won’t last long. Hopefully the weather will start to cooperate soon to get some real work done. My giant piece of allthread also showed up from Mcmaster-Carr for the nosecone. I’m going to reweigh everything and recalculate the Cp/Cd to determine how much nosecone weight I should use to work on that over the weekend.

I’ve been slowly getting back to work. This weekend I spent some time to mount the electronics into the tri-AVbay.

As you can see from the progression below, there isn’t too much to mounting the electronics. I positioned the Altimeter (in this case, a Marsa4), put mounting marks through the screw holes, drilled and tapped the mounting holes, then mounted the altimeter using #4 machine screws and plastic spacers. On the opposite side of the bay, I mounted a 9 volt battery holder, and ran the wires through the bolt cut out.

.

I then drilled holes through the top and bottom of the AVBay,and ran ignition wires from the altimeter through each hole.

Once I had the ignition wires through the hole, I mounted a 4-way screw terminal through the same hole, and secured the ignition wires into one side of the screw terminal. This will allow me to mount the e-matches to the screw terminal instead of threading them through the av-bay, and having to re-seal the AV-bay after each launch. This is a method I have been successful with in the past, although I am well aware these screw terminals will be subjected to the black powder residue , and will likely have to be replaced over time.

I then went through the same process with the Raven. First, it is striking how small the raven is,  when you look at it in this big AV bay. The raven is more complex to install since it uses a common + wiring scheme. While the Marsa4 had discrete connectors for everything (a + and – for each e-match, the battery, and the power switch), the Raven only has 4 terminals and a battery + for everything. This means the power switch has to be inline, and each e-match has to be connected to the same + battery post. Not a big deal, and great if you are putting this in a minimum diameter rocket. With the amount of space in my AV bays, it’s kind of unnecessary. That said, this is my most

when you look at it in this big AV bay. The raven is more complex to install since it uses a common + wiring scheme. While the Marsa4 had discrete connectors for everything (a + and – for each e-match, the battery, and the power switch), the Raven only has 4 terminals and a battery + for everything. This means the power switch has to be inline, and each e-match has to be connected to the same + battery post. Not a big deal, and great if you are putting this in a minimum diameter rocket. With the amount of space in my AV bays, it’s kind of unnecessary. That said, this is my most

The third AV Bay will house a Communication Specialist tracker, and an Altus-Metrum. I haven’t decided on where to mount the power connectors yet. I will probably wait until the very end to determine their optimum placement.

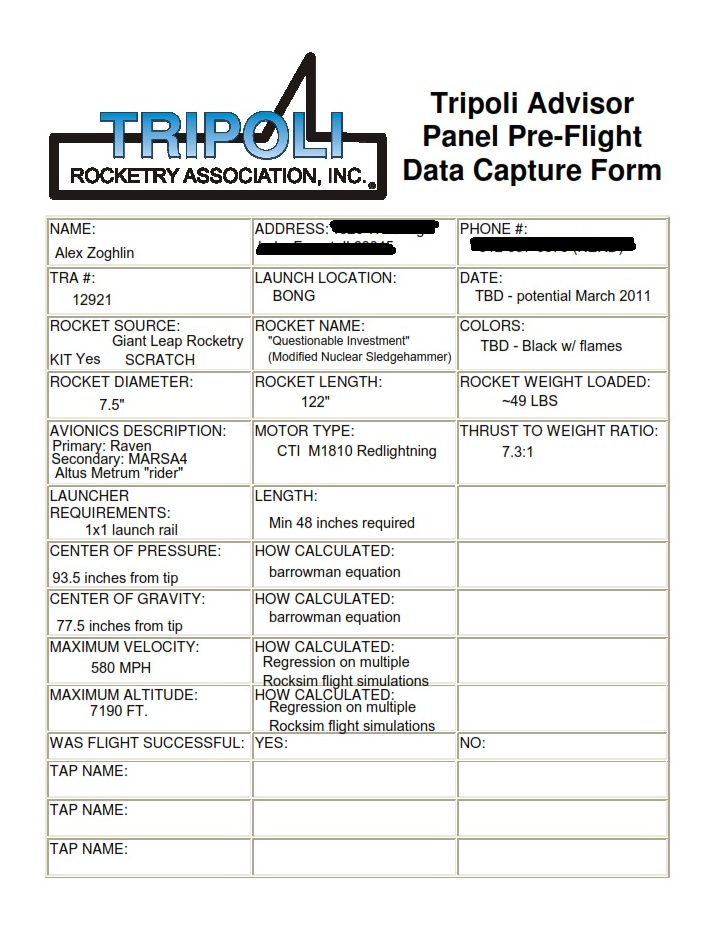

I brought the booster section and AV-Bay up to bong this weekend to show my latest progress, and one of my TAP sponsors asked to see my pre-data capture form. Of course, I didn’t have it, so I’m posting it here to make it easily accessible the next time he asks ![]()

The good news is the new pads for my sander came in (picture on left). The bad news is that means I have a LOT of sanding to do. I took advantage of the weather last week to start the lengthy process of sanding, filling, priming, and sanding again to get a nice smooth finish on the rocket. The glassing of the wings turned out a bit messy because of the limited space (about 1.5”) between the trailing edge of the wings, and the leading edge of the fins. I couldn’t find a way to properly keep enough weight on the curing fiberglass to provide the same clean surface  I ended up with on the wing tops and fin can. Worse, I can’t really fit an electrical sander in that area, so I’ve had to create all sorts of sanding devices to get into that area. You can see what looks like multiple colors on the wings and fins in the picture on the left. This is indicates in some areas I have sanded through the top layer of fiberglass into the Kevlar. That’s not necessarily a good thing,

I ended up with on the wing tops and fin can. Worse, I can’t really fit an electrical sander in that area, so I’ve had to create all sorts of sanding devices to get into that area. You can see what looks like multiple colors on the wings and fins in the picture on the left. This is indicates in some areas I have sanded through the top layer of fiberglass into the Kevlar. That’s not necessarily a good thing,

so I’m now using a different technique to smooth out rough areas, and even out all of the surfaces. I cleaned the surfaces, and sprayed a first coat of primer. The primer will even out many of the smaller pinholes and rough areas, but more importantly, it will allow me to see very quickly when I’ve sanded through into the fiberglass with the big difference in color. My first pass turned out smoother than I had anticipated, but up close, it still looks like Mickey Rourke’s face – that’s not a good thing. I have three major areas left on the rocket:

1) electrical

I still need to install the switches, terminal blocks altimeters, GPS devices, and RF trackers into the rocket and AV-BAY.

2) Nosecone

The Nosecone shoulder still doesn’t fit into the upper sustainer. That means more sanding, or, worst case, cutting the shoulder, and replacing it with a new home-made shoulder from a coupler. I also may need to add weight to the nosecone, and probably foam it. I’ll also need to make bay’s for tracking equipment, install all-thread, a bulkhead, and weight bearing anchor.

3) Sanding & Painting

My plan is to put a really nice airbrushed paintjob on the rocket. Black base with winding flames is my current plan. This will require a very smooth surface, which means lots of priming and sanding. I’m going to wait until the weather turns a little nicer so I can do this outside, and avoid ruining all of the surfaces and cars in nice garage. My wife hasn’t said anything yet about all of the dust, and I don’t want to push my luck.

II will probably be taking a break for a bit on the construction side. Work travel is picking up a lot, three of my four daughters need pinewood derby cars made by mid march, and I still haven’t finished those crayon rockets I gave my kids for Christmas. With that said, I’ do plan to finish #1, #2 by next month so I can get a ‘practice’ launch in before the big event in April. Hopefully my leg will have recovered enough for some rocket hunting

The weather was beautiful yesterday in the Chicago area – a Balmy 52 degrees! I moved the rocket to the garage, but couldn’t resist putting it together for the first time. I still have a fit problem between the nosecone and sustainer, but finally looks like a rocket. It’s supposed to be another nice day today, so I may try to get a few coats of primer on the booster section to see how much sanding and filling work I’ll really need to do – the fin and wing glassing came out much smoother than my usual work.

Unfortunately, I tore my calf muscle about a week & a half ago skiing in Utah, which has really  put a damper on rocket building and pretty much everything else. Worse, I have taken a lot of my OLD rockets out of storage few weeks ago (a Brutus, Maximum Thrust Thunderbird, and a few other 15+ year old HPR rockets) to show my kids, and clean up for flying this weekend at Bong. Given how thick the snow is, I can’t imaging wading through it all in my leg cast trying to recover the rockets

put a damper on rocket building and pretty much everything else. Worse, I have taken a lot of my OLD rockets out of storage few weeks ago (a Brutus, Maximum Thrust Thunderbird, and a few other 15+ year old HPR rockets) to show my kids, and clean up for flying this weekend at Bong. Given how thick the snow is, I can’t imaging wading through it all in my leg cast trying to recover the rockets ![]() . I’ll still go up to see if either of my tap sponsors want to see my progress, but if I fly something, it will be small.

. I’ll still go up to see if either of my tap sponsors want to see my progress, but if I fly something, it will be small.

I was able to get the wings on. First, I had to re-cut the wing slots. The lower portion was glassed over when I made the fin-can, and the whole slot itself wasn’t quite thick enough for the wings to fit through. I repeated the process on the other side, until I could dry fit both wings with a tight fit. One of the issues I will have with the wings is my limited ability to make interior fillets since both sides of the centering rings are already glued in place. First, I filled the interior of the wing’s nomex honeycomb with epoxy and put it into the slot. I let the epoxy ooze out of the honeycomb, then removed the fin. This gave me a line of epoxy on the motor tube where the wing made contact. I repeated that process a few times to build up the epoxy on the motor tube. I then drilled a few half-holes in the wing-slots which allowed me insert a syringe into the body and add epoxy for a sloppy, but effective internal fillet on each side of the wing. Once it was dry, I was able to look through the upper center ring hole I made to pour foam to ensure a the wing was touching, and had a a fillet, and taped it up to cure. I repeated the same process on the other side until both wings were secure w

to get the wings on. First, I had to re-cut the wing slots. The lower portion was glassed over when I made the fin-can, and the whole slot itself wasn’t quite thick enough for the wings to fit through. I repeated the process on the other side, until I could dry fit both wings with a tight fit. One of the issues I will have with the wings is my limited ability to make interior fillets since both sides of the centering rings are already glued in place. First, I filled the interior of the wing’s nomex honeycomb with epoxy and put it into the slot. I let the epoxy ooze out of the honeycomb, then removed the fin. This gave me a line of epoxy on the motor tube where the wing made contact. I repeated that process a few times to build up the epoxy on the motor tube. I then drilled a few half-holes in the wing-slots which allowed me insert a syringe into the body and add epoxy for a sloppy, but effective internal fillet on each side of the wing. Once it was dry, I was able to look through the upper center ring hole I made to pour foam to ensure a the wing was touching, and had a a fillet, and taped it up to cure. I repeated the same process on the other side until both wings were secure w ith internal fillets.

ith internal fillets.

I used the same epoxy and process for the wings, that I used on the fins. Measure and mark the fins and sustainer, lay down tape across the markings, and fill in the middle with epoxy. The process was a little more tricky than the fins because the wing is more than twice the length. Worse, there was not enough clearance between the wing

was a little more tricky than the fins because the wing is more than twice the length. Worse, there was not enough clearance between the wing  and the fin for me to use the same diameter washer I had used on the fins. Eventually, I settled on using my finger to spread, and create the fillet, dipping it in alcohol between pulls, exactly like using the washer. The result was significantly more messy,

and the fin for me to use the same diameter washer I had used on the fins. Eventually, I settled on using my finger to spread, and create the fillet, dipping it in alcohol between pulls, exactly like using the washer. The result was significantly more messy, but just as effective in creating a very smooth fillet, with clean lines. This will reduce the amount of sanding I will have to do before glassing the fins.

but just as effective in creating a very smooth fillet, with clean lines. This will reduce the amount of sanding I will have to do before glassing the fins.

Once everything was dry, I separated the booster from the upper  sustainer which I was using as a lever to keep the lower sustainer in my rocket holder to mount the sustainer upright. It’s foam time! Once again I calculated the empty volume on each wing side, mixed the proper amount (266 ML, half part A, half part B), made a quick funnel out of paper and poured in the foam. Within about 5 minutes, the foam had expanded, almost perfectly to the bottom of the pour hole. I love it when a plan actually works so well! I repeated the same process on the other side, mixing exactly the same amount of foam, but when it was done expanding, I could barely see to top through the pour hole.

sustainer which I was using as a lever to keep the lower sustainer in my rocket holder to mount the sustainer upright. It’s foam time! Once again I calculated the empty volume on each wing side, mixed the proper amount (266 ML, half part A, half part B), made a quick funnel out of paper and poured in the foam. Within about 5 minutes, the foam had expanded, almost perfectly to the bottom of the pour hole. I love it when a plan actually works so well! I repeated the same process on the other side, mixing exactly the same amount of foam, but when it was done expanding, I could barely see to top through the pour hole.  Yikes! Luckily, my kids weren’t around to see the utter failure of math and science’s ability to predict an outcome. II now had no idea how much volume was left in the sustainer, so I had to do the one thing I hate to do…. guess. As you can imagine, I didn’t guess right, and you can see the results on the right – an oozing mess out of the top of the second pour

Yikes! Luckily, my kids weren’t around to see the utter failure of math and science’s ability to predict an outcome. II now had no idea how much volume was left in the sustainer, so I had to do the one thing I hate to do…. guess. As you can imagine, I didn’t guess right, and you can see the results on the right – an oozing mess out of the top of the second pour hole. Luckily, this is not as bad as it looks, and I have a fair amount of experience digging foam out of tight spots thanks to a lot of lawn darts during my magnetic ejection trials. five minutes with my trusty foam extractor (a special grapefruit knife), and a little sanding, and it almost looks like I got it right the first time. I’m now going to move everything out of my office and into my garage in preparation for the massive amount of sanding I’m going to need to do. I would like to thank an anonymous reader for the tip on where to find sanding discs for my 3d sander. A kit of 100 can be had at a retailer named Micro-Mark here. Of course, there are lots of other goodies to be found at Micro-Mark… My package arrived the other day filled with lots of tools I didn’t know I needed until I saw them in the catalog

hole. Luckily, this is not as bad as it looks, and I have a fair amount of experience digging foam out of tight spots thanks to a lot of lawn darts during my magnetic ejection trials. five minutes with my trusty foam extractor (a special grapefruit knife), and a little sanding, and it almost looks like I got it right the first time. I’m now going to move everything out of my office and into my garage in preparation for the massive amount of sanding I’m going to need to do. I would like to thank an anonymous reader for the tip on where to find sanding discs for my 3d sander. A kit of 100 can be had at a retailer named Micro-Mark here. Of course, there are lots of other goodies to be found at Micro-Mark… My package arrived the other day filled with lots of tools I didn’t know I needed until I saw them in the catalog ![]()

Spent much of the day cleaning up from the snowstorm. My four kids were school free yesterday, so I spent the day shoveling, and playing in the snow with them. I did find a little time for the rocket. The picture on the left is the original plastic nosecone. The one on the right is it’s Scotglas fiberglass replacement. Scott Broderick, a WOOSH member happened to have an “extra’ 7.5” nosecone he was willing to sell. I was in the right place, at the right time, as this is a custom nosecone, and they can take forever if you order them. I was thinking about building my own, but a certification rocket didn’t seem like the right vehicle to be learning something so critical. The bad news is because this is a custom nosecone, it didn’t fit my upper airframe at all – the shoulder’s outer diameter is too large for the magnaframe. I was able to sneak away and do a LOT of sanding. No way I was going to do

Spent much of the day cleaning up from the snowstorm. My four kids were school free yesterday, so I spent the day shoveling, and playing in the snow with them. I did find a little time for the rocket. The picture on the left is the original plastic nosecone. The one on the right is it’s Scotglas fiberglass replacement. Scott Broderick, a WOOSH member happened to have an “extra’ 7.5” nosecone he was willing to sell. I was in the right place, at the right time, as this is a custom nosecone, and they can take forever if you order them. I was thinking about building my own, but a certification rocket didn’t seem like the right vehicle to be learning something so critical. The bad news is because this is a custom nosecone, it didn’t fit my upper airframe at all – the shoulder’s outer diameter is too large for the magnaframe. I was able to sneak away and do a LOT of sanding. No way I was going to do  this in my office. You would be surprised at the amount of fiberglass dust even a small sanding can create. For sanding curved surfaces, I use a Crasftman 3D sander. The sander has three floating heads each with their own circular sanding pad. This lets the sander conform to most curved surfaces, reducing the possibility of creating a slat spot using a traditional sander. Unfortunately, they don’t seem to make these anymore, so the pads are becoming a little hard to find. This is an indispensable tool for me, so if someone knows of a reasonable alternative, let me know!

this in my office. You would be surprised at the amount of fiberglass dust even a small sanding can create. For sanding curved surfaces, I use a Crasftman 3D sander. The sander has three floating heads each with their own circular sanding pad. This lets the sander conform to most curved surfaces, reducing the possibility of creating a slat spot using a traditional sander. Unfortunately, they don’t seem to make these anymore, so the pads are becoming a little hard to find. This is an indispensable tool for me, so if someone knows of a reasonable alternative, let me know!

Sounds strange, but I like laminating things. Kevlar, Carbon Fiber, Fiberglass…. doesn’t really matter. Once you understand the process, it opens up a lot of options in both Rocketry, and the real world. In Rocketry, Laminating can provide key missing strength, stiffness, or just plain ruggedness to an otherwise undistinguished model. Combine lamination with foam, and a whole world of custom parts, or odd rockets can be created. In the photo on the right, you see what looks to be the launch of a boring Estes “Super Big Bertha” kit. In fact, the entire rocket was laminated with Kevlar, Carbon Fiber, and fiberglass. The end result – A kit that Este’s recommends launching with a D12-5 engine (max thrust of 29 N, total impulse of 16.8 N-s), that I launched with an Aerotech J570 (max thrust of 1142.5N, total impulse of 973.1N) – an engine about forty times more powerful. During this particular flight, I had packed the chute a bit too tight to fit in my electromagnetic ejection system. Ejection worked, but the parachute never inflated. The rocket fell from 5000 ft, and didn’t have a scratch on it when I found it about 1/2mile away. You can check out the video from the flight below (you can see the camera duct-taped to the side)

Wh ile I didn’t show the original fiberglassing of the magnaframe airframe, there wasn’t a lot of complexity involved. Just as I was leaving HPR rocketry the first time (thanks to the BATF), I had found a company called Fibersock that sold a knitted fiberglass “sock” that let you fiberglass a tube without any seams or complexity. Upon my return to HPR (thanks to Tripoli & NAR beating the ATF in court), Fibersock is gone, but the product is still around. Giant Leap sells a version they call “easyglas” which is exactly the same thing. Basically you pull the sock over the airframe, tie it up on either side, and slather on epoxy laminate. The only modification I’ve made to this process is to use a Teflon coated release film to ensure a very smooth surface, and no air bubbles. This is unlike any peel-ply, or release film I’ve ever used. Very easy to remove, very smooth, super easy to cut and position. Frankly, it’s so well made, when doing tip-to-tip lamination on a small rocket, I’ll often use the same piece of cut release film over and over. Only place I’ve found it i s here.

ile I didn’t show the original fiberglassing of the magnaframe airframe, there wasn’t a lot of complexity involved. Just as I was leaving HPR rocketry the first time (thanks to the BATF), I had found a company called Fibersock that sold a knitted fiberglass “sock” that let you fiberglass a tube without any seams or complexity. Upon my return to HPR (thanks to Tripoli & NAR beating the ATF in court), Fibersock is gone, but the product is still around. Giant Leap sells a version they call “easyglas” which is exactly the same thing. Basically you pull the sock over the airframe, tie it up on either side, and slather on epoxy laminate. The only modification I’ve made to this process is to use a Teflon coated release film to ensure a very smooth surface, and no air bubbles. This is unlike any peel-ply, or release film I’ve ever used. Very easy to remove, very smooth, super easy to cut and position. Frankly, it’s so well made, when doing tip-to-tip lamination on a small rocket, I’ll often use the same piece of cut release film over and over. Only place I’ve found it i s here.

My plan was to to do tip-to-tip lamination of the fins with one layer of Kevlar for strength, and one layer of  fiberglass for finishing. I’ve found Kevlar almost impossible to sand to a smooth finish once it is cured. a thin layer of fiberglass over the top of the Kevlar provides a great base to sand and smooth. I first laid some scrap newspaper over the fins to create the base outline of the fin area. I then cut out the newspaper, and used it as a base to build a cutting template out of foam board. The newspaper gave me the base dimensions, but I needed to add about 2 inches of cloth in each direction to ensure complete coverage, and allow for the Kevlar and fiberglass to wrap around the thick fin edge.

fiberglass for finishing. I’ve found Kevlar almost impossible to sand to a smooth finish once it is cured. a thin layer of fiberglass over the top of the Kevlar provides a great base to sand and smooth. I first laid some scrap newspaper over the fins to create the base outline of the fin area. I then cut out the newspaper, and used it as a base to build a cutting template out of foam board. The newspaper gave me the base dimensions, but I needed to add about 2 inches of cloth in each direction to ensure complete coverage, and allow for the Kevlar and fiberglass to wrap around the thick fin edge. A typical rocket fin made out of g10 fiberglass would be about .093, to .125 inches thick. My fins and wings were about five times thicker, requiring some creative solutions down the road. My main goal in creating the laminating fin can is to ensure the fin’s don’t rip off during flight, and increase their strength in case the rocket lands funny. I plan on putting a LOT of time into the finish (I have an airbrush, and like to play….), and would be crushed if a great flight ended with a broken fin.

A typical rocket fin made out of g10 fiberglass would be about .093, to .125 inches thick. My fins and wings were about five times thicker, requiring some creative solutions down the road. My main goal in creating the laminating fin can is to ensure the fin’s don’t rip off during flight, and increase their strength in case the rocket lands funny. I plan on putting a LOT of time into the finish (I have an airbrush, and like to play….), and would be crushed if a great flight ended with a broken fin.

My normal method for tip-to-tip lamination is to use a fairly standard vacuum bag sealing process. Because of the size of the rocket, I could not create a bag that would encapsulate the entire lower sustainer with fins and keep a good seal. This may be possible, but I spent a LONG, LONG time on it. The primary advantage of vacuum sealing is it creates a lot of pressure on the lamination, squeezing the excess epoxy out through the r elease film (reducing weight), and creating a good mechanical connection between the epoxy, fabric, and fins. In my case, I was less concerned about weight, but wanted to make sure I would have a good mechanical bond, including the thick edge of the fins. There are lots of great tutorials on the web on how to do tip-to-tip lamination without vacuum sealing, but all of the ones I have seen assume you have a fairly thin fin. The best I’ve seen is here. In my case, needed ballast on the lamination to keep it tightly bonded to the fin, but I needed pressure on the edge of the fin as well. Using a fin jig as John did in the link will almost guarantee there won’t be enough pressure on the edge of the fin. I needed some kind of Ballast that would mold around the fin keeping pressure over the entire surface area during curing. I settled on using a liquid as the weight, in a waterproof bag that could hang over the fin.

elease film (reducing weight), and creating a good mechanical connection between the epoxy, fabric, and fins. In my case, I was less concerned about weight, but wanted to make sure I would have a good mechanical bond, including the thick edge of the fins. There are lots of great tutorials on the web on how to do tip-to-tip lamination without vacuum sealing, but all of the ones I have seen assume you have a fairly thin fin. The best I’ve seen is here. In my case, needed ballast on the lamination to keep it tightly bonded to the fin, but I needed pressure on the edge of the fin as well. Using a fin jig as John did in the link will almost guarantee there won’t be enough pressure on the edge of the fin. I needed some kind of Ballast that would mold around the fin keeping pressure over the entire surface area during curing. I settled on using a liquid as the weight, in a waterproof bag that could hang over the fin.

I should probably mention I spent a LOT of time sanding down the fillets. I also installed the boat tail, as I decided I wanted some lamination over the edge to ensure a smooth transition between the airframe and boat tail for

finishing. That added even more sanding. Once complete, I ‘painted’ on a layer of epoxy (US Composites), put down the Kevlar, Wet the Kevlar, then added the fiberglass. Wet the fiberglass, then added the Teflon release film. Wet the release film, then added a Polyester breather cloth on top to suck up the excess epoxy, and provide a surface for me to put down my ballast. I filled three zip-lock bags about 3/4 with water as my ballast. One bag

per fin, and one for the airframe & fillets. I know it’s kind of hard to see, but the bags on the fins hang over the side, providing positive pressure on the lamination during the cure. I left everything for 24 hours. Removed the water bags, then the Teflon release film.

As you can see, it came out really, really well. I was a little worried with the lack of significant weight on the wings, I would get a lot of air bubbles in the lamination over the fillets. big curves like this are notoriously difficult to make sure the Kevlar and fiberglass stay pressed against the fillet, especially when the water bags were pulling on the edges of the weave to secure them around the fins. . There wasn’t one bubble tip-to-tip. Happy with the process, I then repeated it twice more for each side. I only had two issues with the process, neither was too critical. First, on the edges of each Fin, I had doubled the lamination. The second layer of lamination didn’t have the pressure of the first, which you can see looks like an air bubble along the leading edge of the fin. This isn’t a big deal, As I will be sanding down the second layer, which is mostly fiberglass. The second issue you can also see in the picture on the left is a few epoxy runs. This is a run of epoxy over a side of lamination that has already dried. Again, not too big of a deal, just requires sanding. As you can see from the picture above, I had to laminate over the pre-cut slots for the wings to get a true tip-to-tip fin can. The pre-cuts were already too small, so the next phase will be to sand the fin can, re-cut the wing slots, and install the wings. Should start to look like a real rocket soon.

I only had two issues with the process, neither was too critical. First, on the edges of each Fin, I had doubled the lamination. The second layer of lamination didn’t have the pressure of the first, which you can see looks like an air bubble along the leading edge of the fin. This isn’t a big deal, As I will be sanding down the second layer, which is mostly fiberglass. The second issue you can also see in the picture on the left is a few epoxy runs. This is a run of epoxy over a side of lamination that has already dried. Again, not too big of a deal, just requires sanding. As you can see from the picture above, I had to laminate over the pre-cut slots for the wings to get a true tip-to-tip fin can. The pre-cuts were already too small, so the next phase will be to sand the fin can, re-cut the wing slots, and install the wings. Should start to look like a real rocket soon.

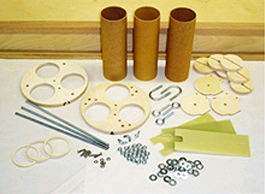

This may sound strange, but one of the main reasons I was attracted to this kit was the TRIAD AV-BAY with three separate 2.5” x 8” sealed bays for electronics. Electronics are one of my favorite parts of large rockets, and this will give me the opportunity to cram a whole lot more than normal. Longer term, I plan to use the 2.5” x 8” as a standard av-bay size so that my sled-mounted electronics can be moved from rocket to rocket without requiring any custom work, or disassembly of the electronics. Here’s the parts list for the AV-bay:

Three 2.5” x 8 phenolic tubes

Three 2.5” x 8 phenolic tubes As you can see, this was a comprehensive kit, with most of the major work already completed. Combined with the great set of directions Giant Leap provided, I assumed this would be a piece of cake. N othing is ever as it seems